When working with electronics or metalwork, the importance of a clean, strong, and lasting joint cannot be overstated. One of the crucial components that ensure the success of soldering is solder flux. While not as widely discussed as soldering irons or solder wire, solder flux plays a fundamental role in the efficiency and reliability of the soldering process. This article explains what solder flux is, why it’s essential, and how to use it correctly for the best soldering results.

What Is Solder Flux?

Solder flux is a chemical cleaning agent used in both electronics soldering and metal joining processes. Its primary role is to remove oxidation from metal surfaces, facilitate the wetting of the metal during the soldering process, and ultimately help in forming solid and electrically conductive joints.

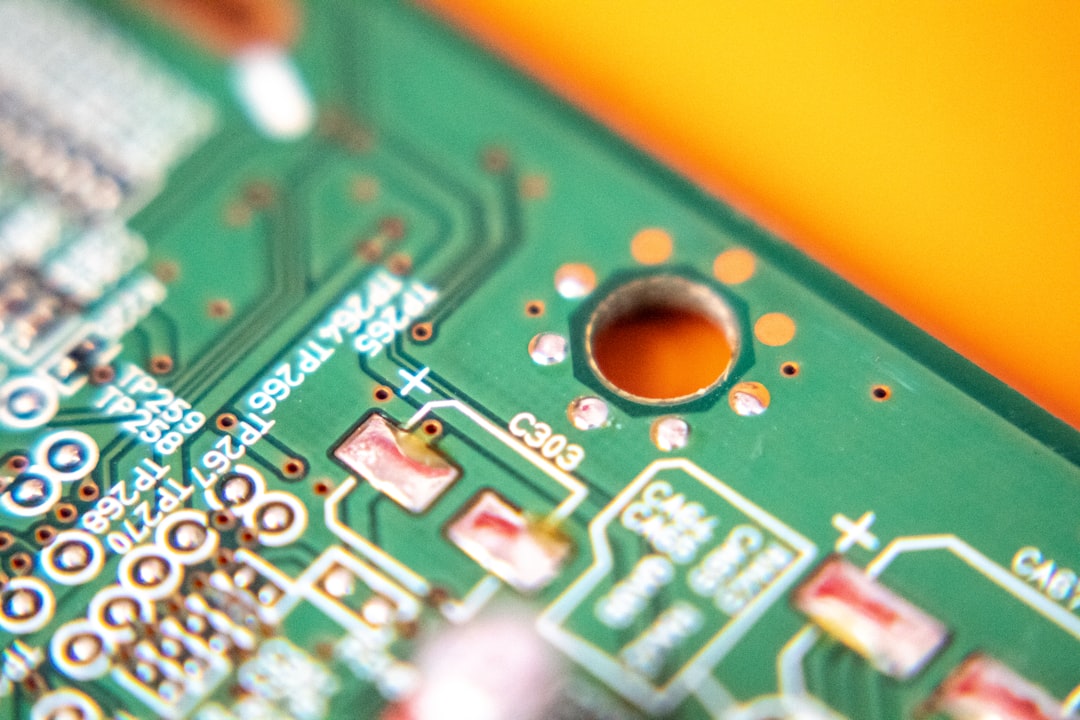

When metals are exposed to air, they naturally form a thin layer of oxide on their surface. This oxide can prevent solder from flowing properly and bonding with the metal. Flux reacts with these oxides to clean the metal, making it easier for the solder to adhere smoothly and securely.

Types of Solder Flux

Choosing the right type of flux is crucial, especially for different applications. Here are the main categories of solder flux:

- Rosin Flux: Derived from pine sap, this is widely used in electronics. It’s non-corrosive and suitable for most electrical circuits. It comes in three varieties: R (pure rosin), RMA (rosin mildly activated), and RA (rosin activated).

- Water-Soluble Flux: Contains organic acids that are stronger cleaners than rosin. However, this type must be cleaned off thoroughly after soldering to prevent corrosion.

- No-Clean Flux: As the name suggests, this flux does not need to be cleaned after use. It’s ideal for circuits where post-solder cleaning is difficult or impractical, though it may not clean as effectively as other types.

- Acid Flux: Generally used in plumbing and sheet metal work, this flux is corrosive and not recommended for electronics as it can damage circuit boards.

Why Use Solder Flux?

Many beginners to soldering often wonder whether flux is really necessary, especially since some soldering wires come with flux cores. Though flux-cored solder offers convenience, understanding and applying additional external flux can greatly improve joint quality and longevity.

Here’s why using flux is advantageous:

- Cleaning: Flux removes oxidation from metal surfaces for better electrical connectivity.

- Improved Wetting: It helps molten solder spread more evenly, avoiding clumps or cold joints.

- Heat Efficiency: It aids the transfer of heat from the soldering iron to the work area efficiently.

- Joint Strength: It improves overall mechanical integrity of the soldered joint.

How to Use Solder Flux

Using flux is a simple yet precise process. It must be applied correctly to yield optimal results in your soldering project. Here’s a step-by-step guide:

- Clean the Work Surface: Ensure that both the component leads and the PCB pads or metal surfaces are clean. Remove any grease, oxidation, or old solder using isopropyl alcohol or a abrasive brush if needed.

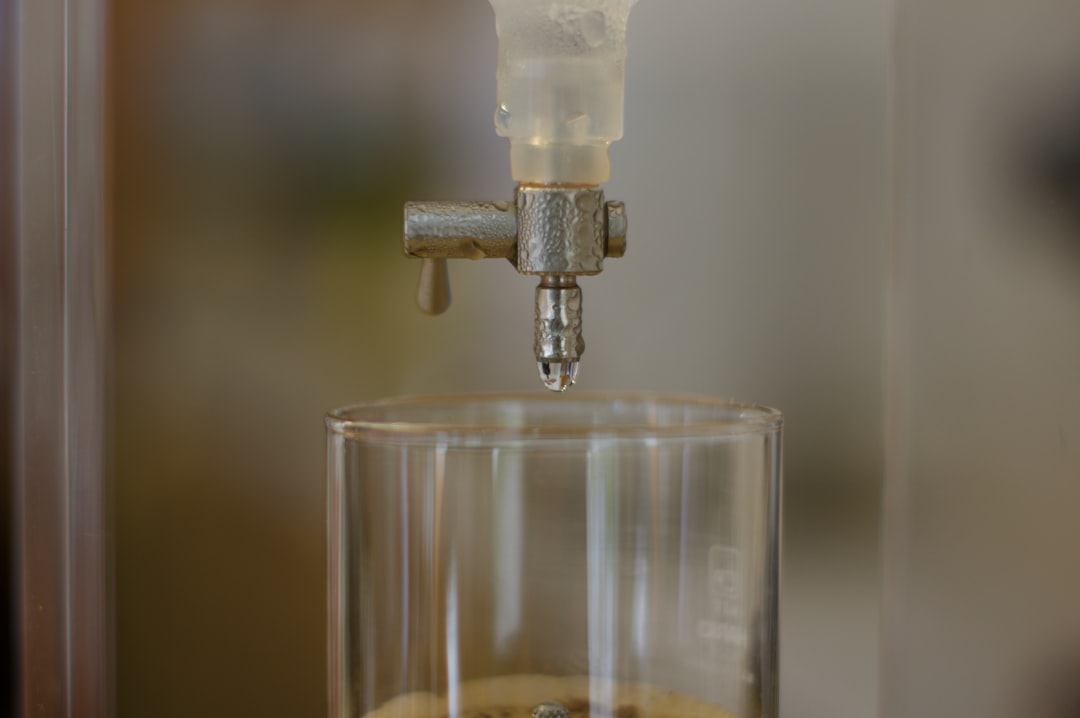

- Apply Flux: Dip a brush or syringe applicator in the flux and apply a thin, even layer over the area to be soldered. You don’t need much—just enough to form a light coat.

- Heat the Joint: With a heated soldering iron, bring the tip into contact with the metal surface. The flux will start to activate, melting and removing oxides as it heats up.

- Apply Solder: Introduce solder to the joint while maintaining contact with the iron. The solder should flow smoothly and settle into place without resisting.

- Remove Excess Flux: After soldering, especially with water-soluble or rosin activated fluxes, you should clean off the residue. Use alcohol and a brush or flux remover for this purpose.

Tips for Effective Flux Usage

To make the most of solder flux, consider the following best practices and tips:

- Use the Right Type for the Job: Electronics should generally use rosin-based or no-clean flux, while plumbing work may require stronger acid-based fluxes.

- Don’t Overapply: Using too much flux can make a mess and may lead to corrosion if not adequately cleaned.

- Check the Compatibility: Always ensure the flux is appropriate for the metals you are working with.

- Storage Matters: Keep flux sealed and stored in a cool, dry place. Exposure to air and light can degrade its chemical properties.

- Protect Your Workspace: Use a flux-safe mat or surface to prevent stains and corrosive damage.

Common Flux Mistakes to Avoid

Even though solder flux is easy to use, some common mistakes can affect your soldering quality:

- Not Cleaning After Soldering: If using rosin or water-soluble flux, always clean the residue. Ignoring this step can cause corrosion over time.

- Using the Wrong Flux: Using acid flux on electronics can cause irreversible damage. Always check the label.

- Contaminating the Tip: Touching the soldering iron tip directly into a container of flux can contaminate your tools and reduce their lifespan.

FAQ: Solder Flux

- Q: Can I solder without flux?

A: While it’s possible with flux-core solder, using additional flux improves joint quality and reliability, especially on oxidized or dirty surfaces. - Q: Is flux conductive?

A: No, flux is generally non-conductive when dry. However, some flux residues can be mildly conductive or corrosive, which is why cleaning is sometimes necessary. - Q: How do I clean flux residue?

A: Use isopropyl alcohol (preferably 90% or higher) and a soft-bristle brush or specialized flux remover. For water-soluble fluxes, distilled water may also be used. - Q: Can flux go bad?

A: Yes, flux can degrade over time. Always check the expiration date and store it properly to maintain effectiveness. - Q: What’s the difference between flux and solder paste?

A: Solder paste is a combination of powdered solder and flux. It’s primarily used in surface-mounted devices (SMDs) and reflow soldering.

In conclusion, solder flux is an indispensable tool in both electronic and metalwork soldering. Understanding its types, proper application techniques, and the benefits it offers can significantly improve your soldering results. Whether you’re repairing a circuit board or crafting metal jewelry, a good handle on flux usage can take your skills to the next level.